Made in Italy goes green

Already distinguished by an unwavering commitment to the Made in Italy movement - a real "vision for production" involving the entire company chain, from the arrival of raw materials to outgoing customer shipments, with the aim of offering a product made entirely in Italy - Vimar is increasingly pushing its production cycle towards a lower environmental impact.

Only by taking care of the environment surrounding us can we continue to grow steadily and together over time. The Marostica company - a leader in the electric and electronic components sector, the home & building automation sector and (after acquiring Padua-based Elvox) the video door entry, CCTV and gate automation sector - is well aware of this, and has actually been adopting a "green" production policy for some time.

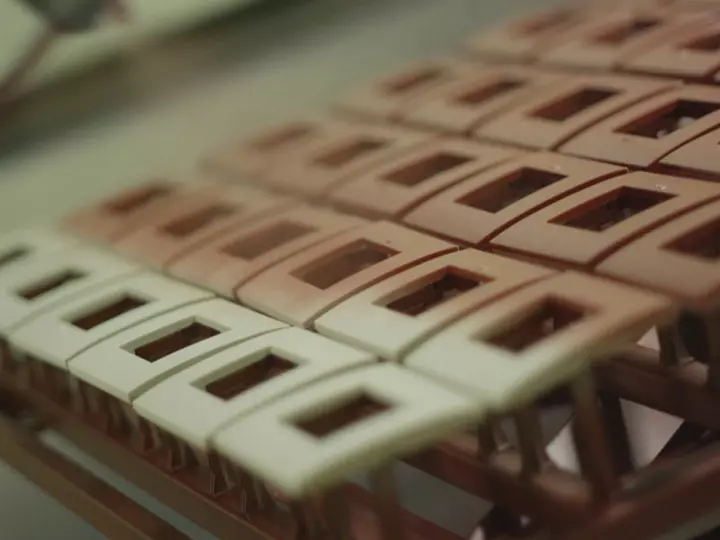

Environmental design, with its pivotal principles of separation, information and the creation of a culture, is an articulated programme applied across the entire production cycle. Beginning with correct waste separation, it actually allows 60% of plastic waste material and the majority of metal waste material to be recycled; Research & Development are then informed of any difficulties encountered when separating the various components, to ensure that the product is designed at the outset with the intention of being totally dismantled and recycled at the end of its life. It also involves departmental training activities to ensure that waste is separated at source and all suitable material reused.

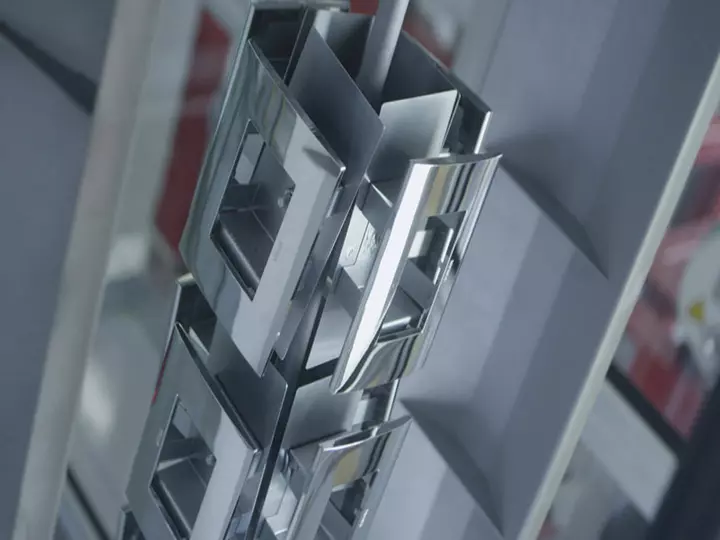

Manufacturing also takes an "ecological" approach. For years now our painting department has only been using water-based or UV cross-linked paints, and the few remaining solvents are entirely recycled. This has made it possible to reduce atmospheric emission of VOCs (Volatile Organic Compounds) to below 50% of the limits set out in the strictest European standards. Galvanic bath treatments for metal finishes are progressively being eliminated. In place of this highly polluting process, the innovative and greener MSD (Magnetron Sputtering Deposition) treatment is being adopted, which uses physical rather than chemical principles to eliminate all harmful emissions. Argon ions are sputtered onto metal plates in a vacuum chamber, releasing atoms which deposit on the product to create the required finish.

Plus, to encourage disposal by our customers, all packaging is completely recyclable. The cardboard single product packs and containers are made from recycled materials. Our corrugated cardboard multi-product boxes for transportation are printed using water-based inks with no harmful substances and use only ecological glues.

To illustrate the fact that eco-sustainability is much more than a positive idea, the Marostica company headquarters - covering an area of 11,000 square metres - has been equipped with a photovoltaic module system which guarantees an annual production of 710,000 kWh, satisfying 12% of site energy requirements. This prevents 350,000 kg of carbon dioxide, 8,700 kg of sulphur dioxide, 6,800 kg of nitrogen oxides and 312 kg of fine particles from being released into the atmosphere.

Made in Italy also stands for this: safeguarding and respecting the environment and its inhabitants.

Published on